Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

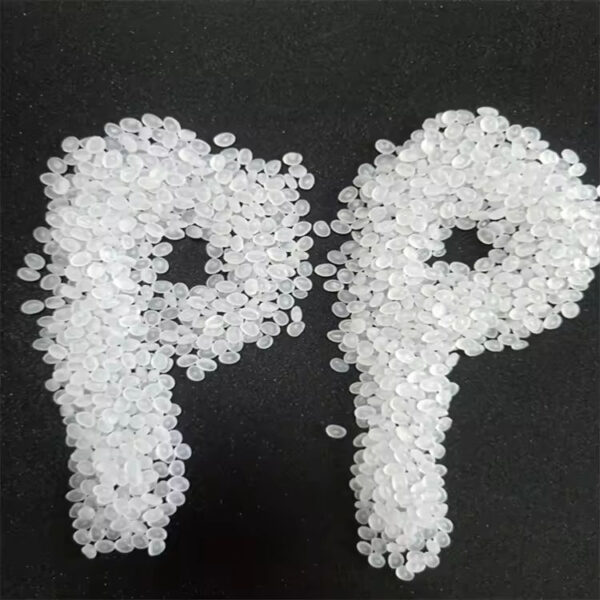

Brief description:pp plastic

Linear High Transparency Random Copolymer Polypropylene RP340R

Product Description

PP-R, MT05-400L (RP340R) is a polypropylene random copolymer with good fluidity, mainly used in injection molding. RP340R has the characteristics of high transparency, high gloss, high-temperature resistance, and good injection dimension stability. The product has passed YY/T0242-2007 medical testing and GB 4806.6-2016 food and drug performance testing. Household daily necessities, stationery, containers, packaging, syringes, etc.

Basic Information

Origin: China

Model Number: PPR340R

MFR: 28 (2.16kg/230°)

Packaging Details: 25 kgs/bag

Port: Qingdao

Payment Method: T/T LC at sight

Customs Code: 39021000

Technical Data

| ITEM UNIT METHOD TYPICAL VALUE

|